The smart home, the quantified self, the internet of things – theyu2019re all spurred by easier access and sharing of information. Many of the communication giants, like Qualcomm, offer low cost radios (WiFi, BTLE, 802.15.4) with minimal form factor, robust SDKs, short lead times, development boards, and great field application engineer support. Additionally, companies like Particle (formerly Spark.io), Electric Imp, and others offer plug-and-play connectivity accommodating makers across the globe.

From connected lights to connected stove top knobs, itu2019s never been easier to add a WiFi connection to everyday objects.”

In 2014, there were $529 million pledged towards successfully funded projects on Kickstarter. Compare that to $480 million in 2013 and just below $320 million in 2012. Projects like Hello Sense, Coolest Cooler, Pebble Time, and Notion proved many times over that compelling, innovative hardware can tip the scales.

nBeyond Kickstarter and Indiegogo, third party logistics (3PL) providers, like Backerkit, allow hardware startups to focus on development and execution instead of fulfillment and shipping while manufacturing services specialists like PCH Access, are major catalysts for producing incredibly robust, secure, and aesthetically appealing products.nn “Image Credits:igor kisselev (opens in a new window) / Shutterstock (opens in a new window)

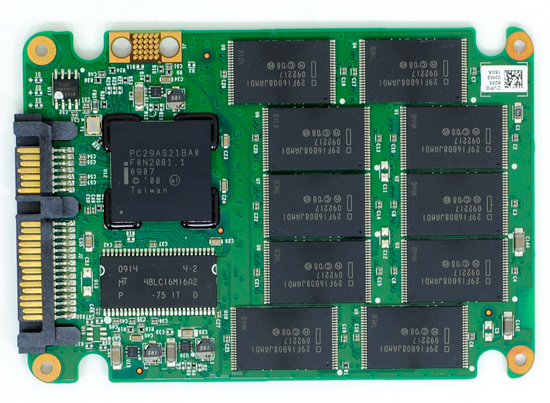

One of the biggest limiters for hardware startups has always been the time it takes to turn around prototype iterations. Itu2019s not uncommon for companies to require 10 to 15 board spins before a final product is ready. While quick-turn PCB fabricators have been plentiful for a number of years, the ability to quickly populate boards with surface mount parts certainly hasnu2019t.

Enter companies like Tempo Automation, Macrofab, and efficient, turnkey contract manufacturers like Vergent Products. Not only can boards be fabricated, populated, tested, and shipped quickly, hardware startups can get a much more reliable and informative outlook on their production manufacturing costs which is imperative for future success.”

3D printing has been a major catalyst for hardware startups in minimizing the financial impact of designing great product enclosures. Soft tooling can run in the tens of thousands of dollars range. Do that three times and the bills really start adding up. Not to mention, production tooling can then be $50k to $100k more!

With the advent of affordable, dimensionally stable 3D printing, testing enclosure designs is as easy as a CAD program and a few hours of print time.”

Nest and Fitbit are great examples of how information and quantification open the doors for incredible expansion. Integrations amongst hardware platforms through HomeKit, Works with Nest, IFTTT and others allow devices to perform beyond their specific capabilities. On Nestu2019s side, something that starts as simply a thermostat expands to lowering energy bills, helping utility companies increase efficiency, and even decreasing insurance premiums.

Many other hardware offerings are growing in similar capacities: they enter the consumer world with a core function then branch out to add value in ways the consumer may have not initially expected. The result is delight, intrigue, and brand loyalty.”

From the dot-com boom in the late 90’s/early 00’s to the SaaS rage of the last couple years, there’s a perpetual innovation engine spinning its wheels and entrepreneurs across the globe are always looking to grab on when the time is right.

For many years, hardware has lagged behind software because of price, specialization, and the speed of innovation. Recently though, more startups are taking up the challenge thanks to the Internet of Things.